VPM 360

VPM 360 is a ventilation unit with heat recovery via a reversible heat pump that can both cool and heat the supply air. The integral heat pipe increases both the cooling and the heating effect and it therefore ensures a good COP.

VPM 360 is used for ventilating buildings with a requirement for good air quality, for instance if rooms or spaces with polluted air are ventilated via the central ventilation system. Such spaces could include commercial kitchens, lavatories and changing rooms. Extract air and supply air are kept separate, and particles will therefore not be passed from one to the other.

The heat pump is integrated in the unit, and it is therefore a compact unit that does not take up much space in the building. At the same time you avoid having to install an external cooling unit outside on the ground and on the roof.

Airflow (see planning data for SEL/SFP values)

Min : 900 m3/hMax : 4400 m3/h

|

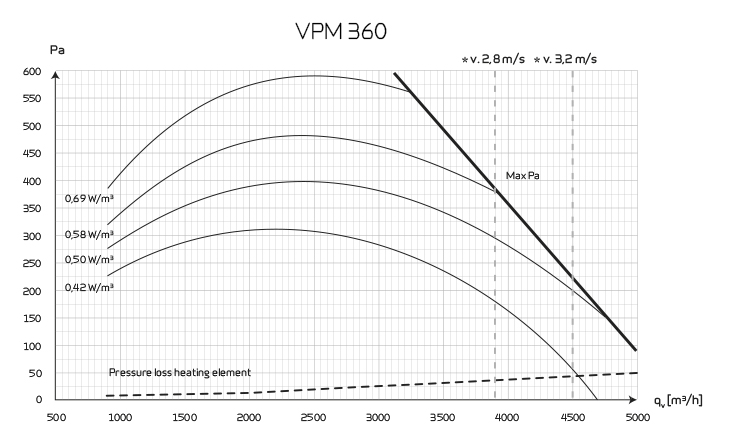

CapacityMax Pa capacity of standard unit, Pt,ext as a function of qv, with regard to SFP-values. SFP-values according to EN13053 for a standard unit with ISO ePM10 >60% (M5) & ISO ePM1 50% (F7) filters an no heating element. * Airflow speed above evaporator is measured at meters per second. Attention! The SFP values are measured and stated as a total value for both fans. |

|

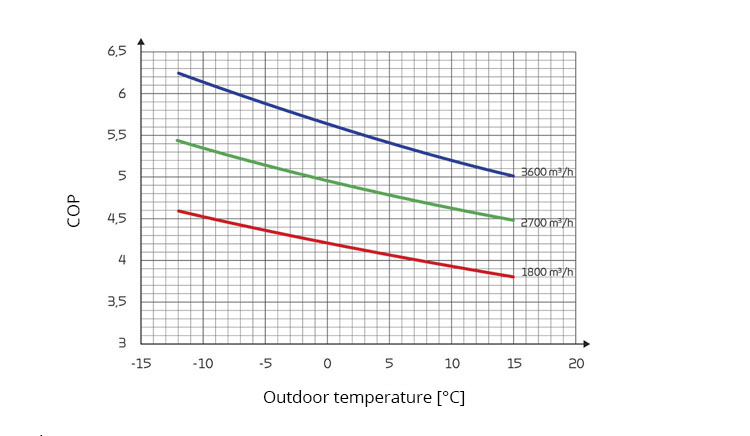

COP (air/air)Heat effect factor COP [-] supply air as function of outdoor temperature [°C] and volume flow qv [m3/h]. According to EN14511, extract air = 21 °C. |

|

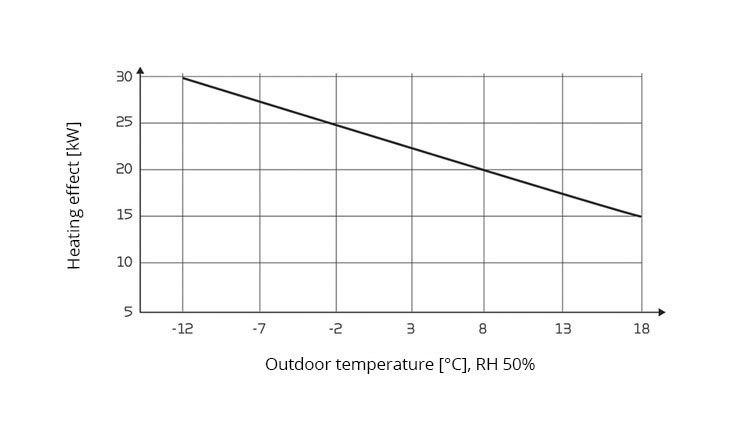

Heat effectHeat effect Qc [W] as a function of qv 3,600 m3/h and outdoor air temperature [°C].

|

|

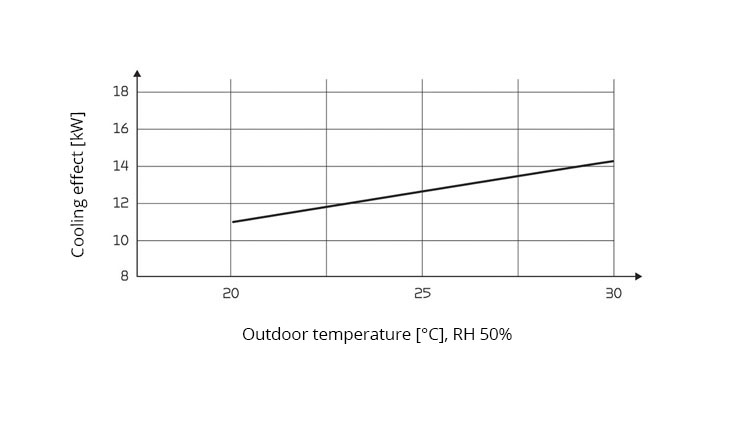

Cooling effectSupply air temperature [°C] as a function of outdoor air temperature [°C] and volume flow qv 3,600 m3/h balanced flow.

|

|

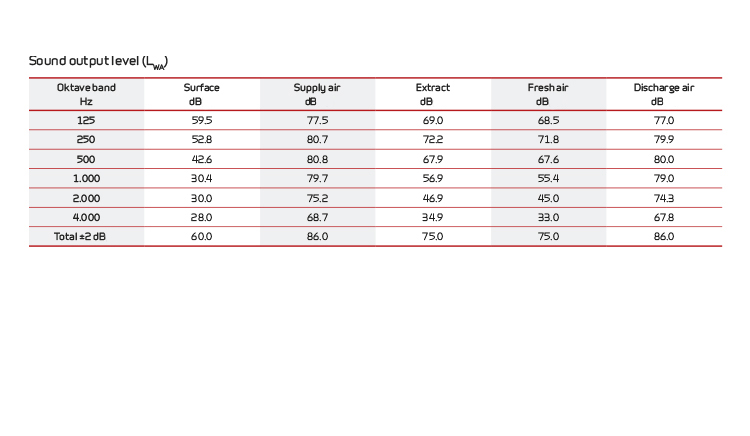

Sound dataSound data for qV = 3,600 m3/h and Pt, ext = 250 Pa according to EN 9614-2 for surfaces and EN 5136 for ducts. Sound output level LWA drops with falling air volume and falling back pressure. Sound output level LpA at a given distance will depend on acoustic conditions in the place of installation. |

|

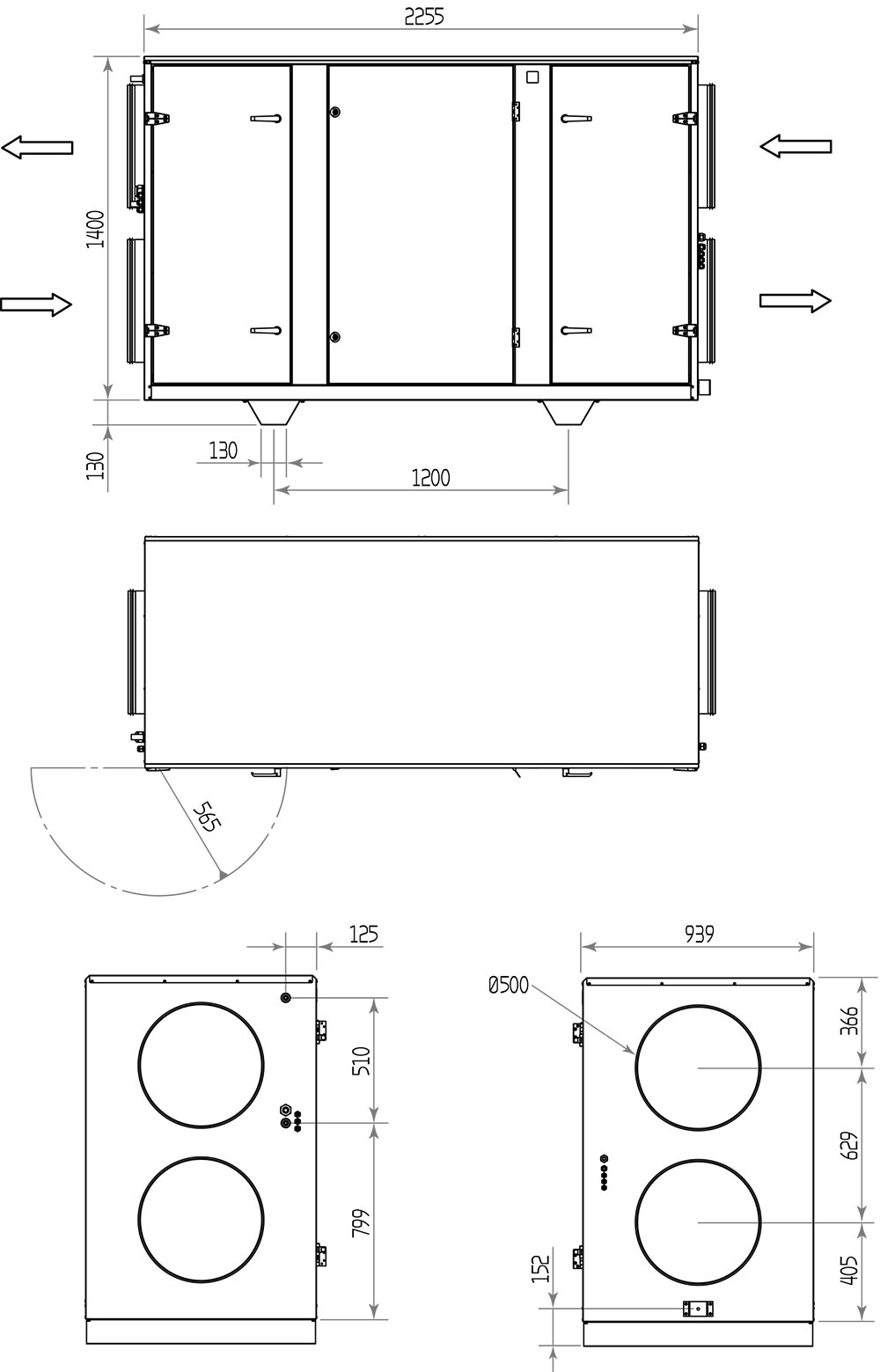

Dimensional drawing VPM 360:

Connections: |

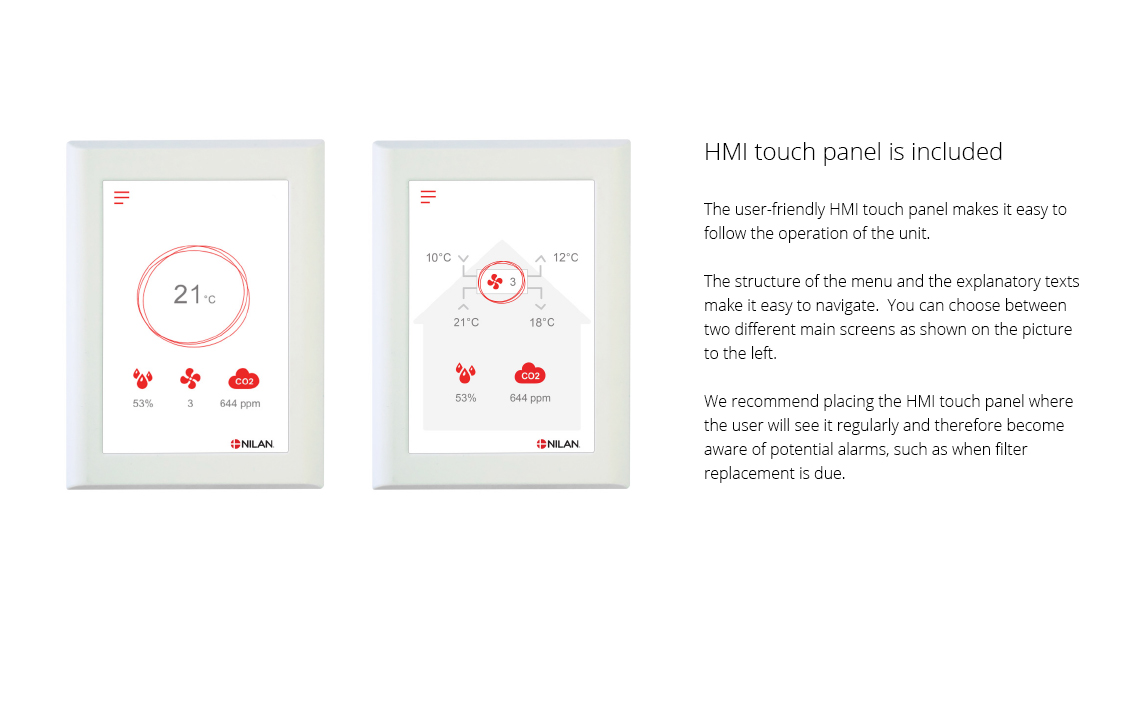

The CTS602 control system is an advanced control system with many settings options. The control system is supplied with factory default settings that can be adapted to the operational requirements in order to achieve best possible operation and utilisation of the unit. The HMI Touch panel provides an overview of the current operation of the unit, and the structure of its menu makes it easy to navigate for both user and installer. There is an option for selecting between 2 front page images for the main screen. External communication The CTS602i control unit communicates by default with Modbus RTU RS485 communication. A CTS system using this form of communication can easily be connected to the unit.

You can find further information about all the functions in the Software and Installation instructions for the unit.

|

Nilan CTS 6000 enables you to control and monitor Nilan commercial ventilation units online via a computer. You can access your units from anywhere in the world. By using a weekly or annual program, the unit can be set to operate automatically with regards to e.g. operating times, room temperatures, fan speed levels and alarms. The CTS 6000 enables you to monitor the operating mode of the unit closely. Whoever it concerns will automatically be notified via email about all types of operational disruptions, alarms, and maintenance notifications. Operational disruptions can then quickly be dealt with and, at the same time, you will safely know when to carry out maintenance and when to plan services. Functions Advantages Add-on |

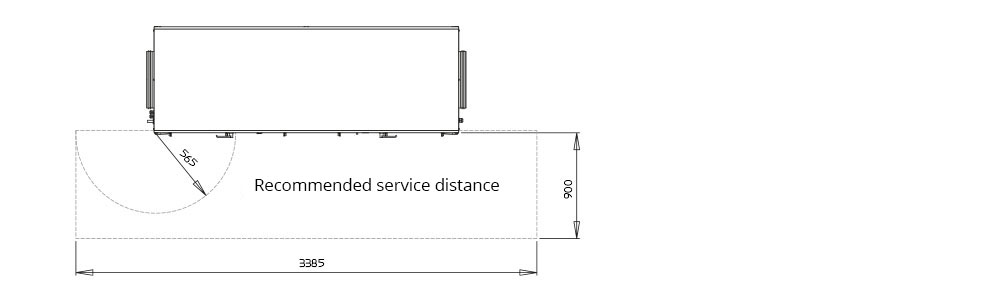

ATTENTION! Good clearance in front of the unit is recommended. When positioning the unit, you should always consider future services and maintenance. It must be easy to replace filters and it must be possible to replace fans or other components. There must be space for easy cleaning of the unit. When cleaning the unit, water may run out of cleaning and condensation drains. There must therefore be space for mounting water locks at condensate drains as well as any. The unit must be level to enable proper drainage from the condensate tray.

ATTENTION! The unit produces a limited level of noise and vibrations, but you should still take into account potential vibrations that can spread from the unit to individual parts of the building. In order to separate the unit from the underlying surface, it is therefore recommended that you fit vibration absorbers under the unit. There should be approx. 10 mm distance to other building components and to permanent fixtures. Condensate drain

|

Motor and motor control

Data for ecodesign

Conditions according to EC327/2011

|