VR 120

The VR 120 is a ventilation unit designed for central ventilation of buildings. The unit is equipped with a rotary heat exchanger that ensures stable passive heat recovery with high efficiency and contributes to a comfortable indoor climate all year round. The series also offers natural cooling (free cooling), integrating both comfort and energy efficiency into daily operation.

The VR 120 is suitable for installation in schools, offices, meeting rooms, and other commercial premises where comfort, energy efficiency, and operational reliability are required.

The VR series features a self-supporting frame and 50 mm insulation, providing a durable and compact unit that is easy to place in technical rooms with limited space. Flexible spigot positioning and universal connection options make it easy to adapt the installation to the building.

The VR 120 is designed with a focus on simple installation and easy access for servicing.

Airflow (see planning data for SEL/SFP values)

Min : 0 m3/hMax : 1950 m3/h

Heating data - condensation exchanger

|

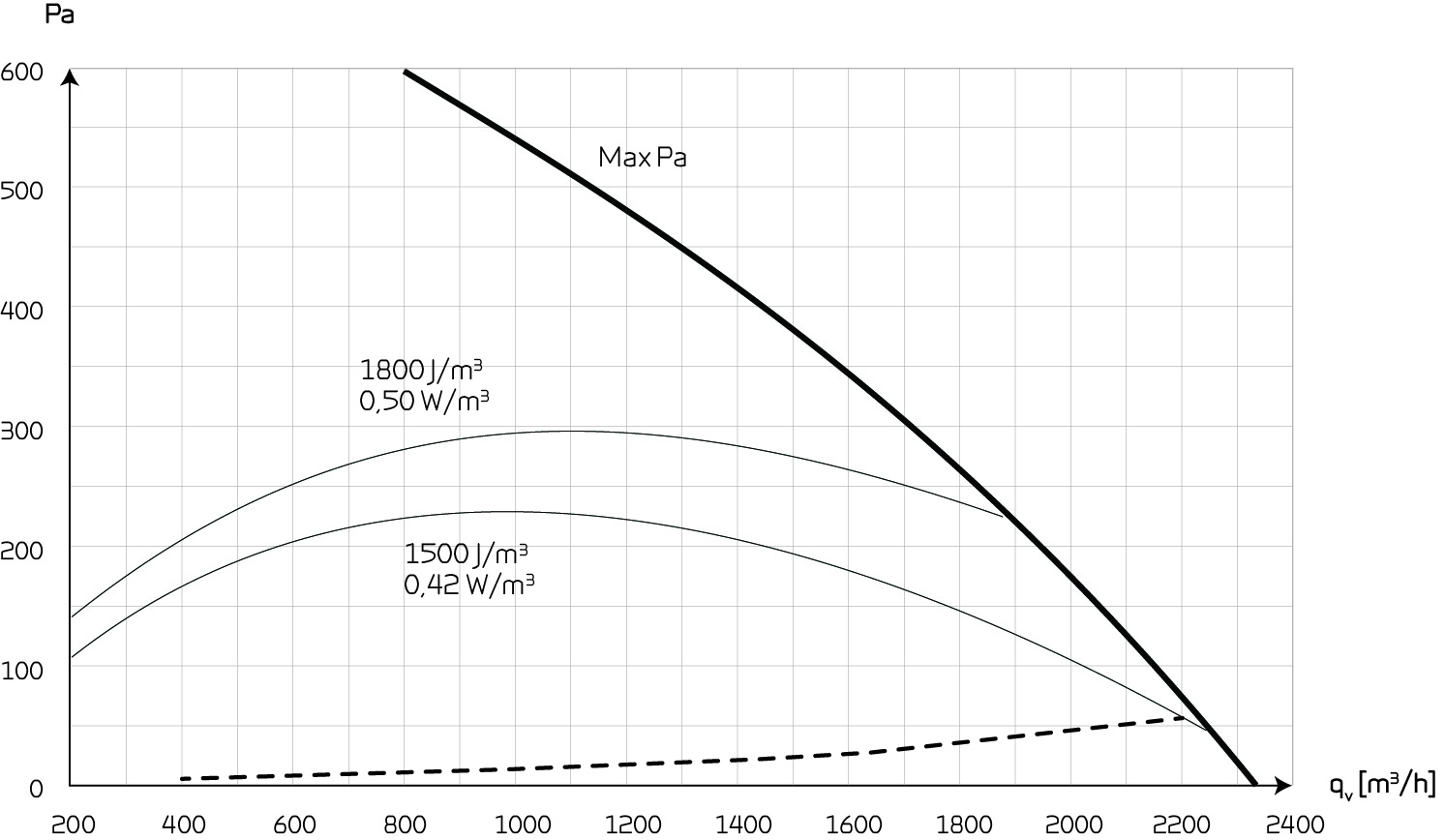

Capacity (condensation exchanger)The following design data is calculated on the basis of a condensation exchanger. Max Pa capacity of standard unit, Pt,ext as a function of qv, with regard to SFP-values. SFP-values according to EN13053 for a standard unit with ISO ePM10 >60% (M5) & ISO ePM1 50% (F7) filters an no heating element. Attention! The SFP values are measured and stated as a total value for both fans. |

|

Temperature efficiencyTemperture efficiency for rotatry heat exchanger according to EN308 (dry). |

|

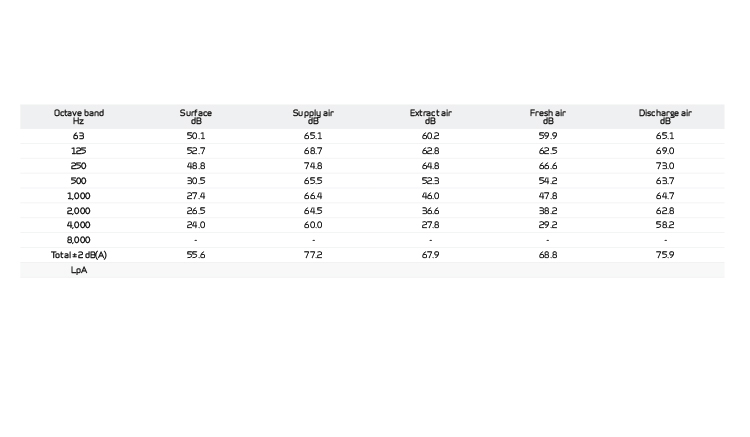

Sound dataSound data for qV = 1200 m3/h and Pt, ext = 200 Pa according to EN 9614-2 for surfaces and EN 5136 for ducts. |

|

|

|

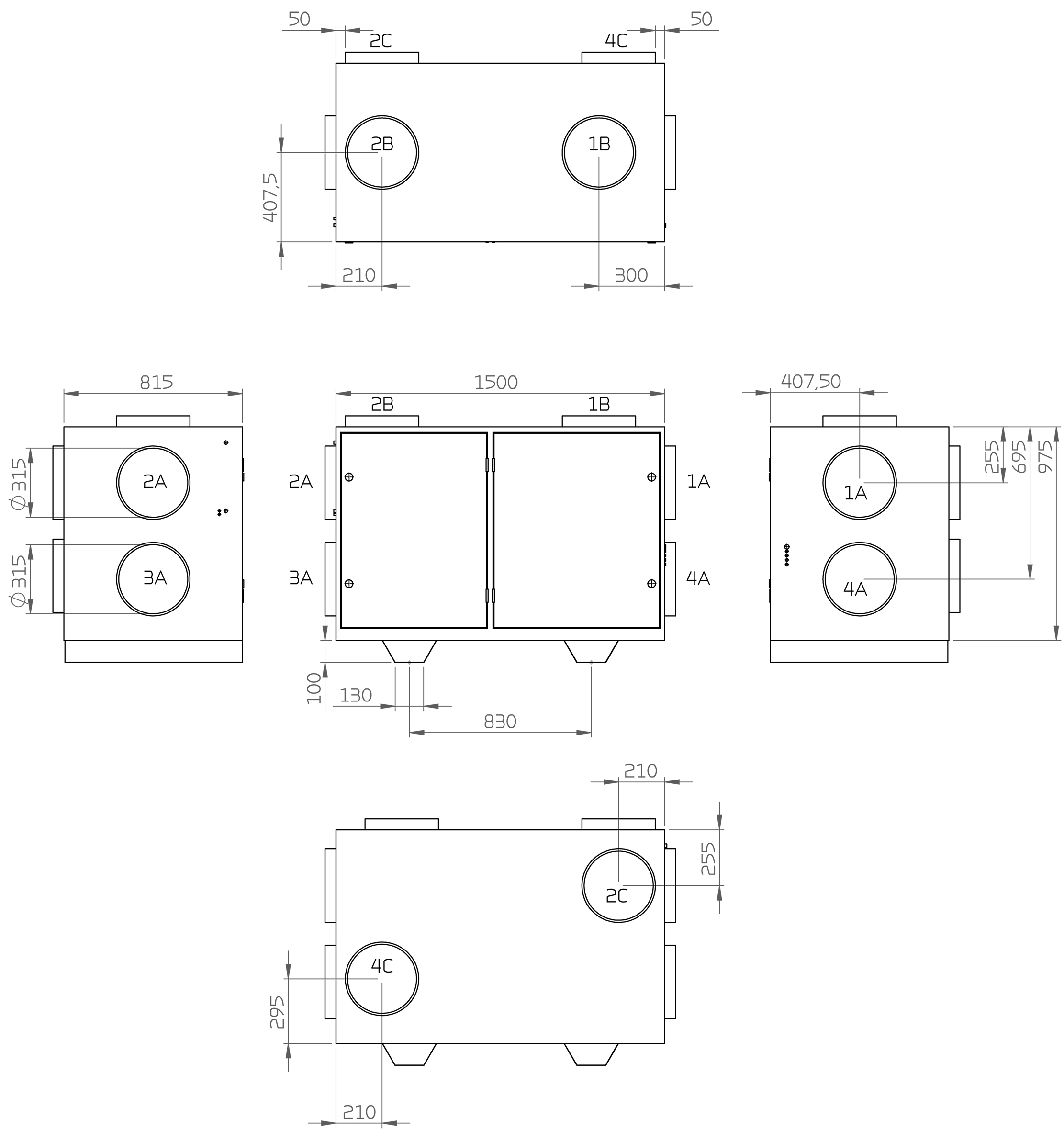

Dimensional drawing VR 120 (Left version):

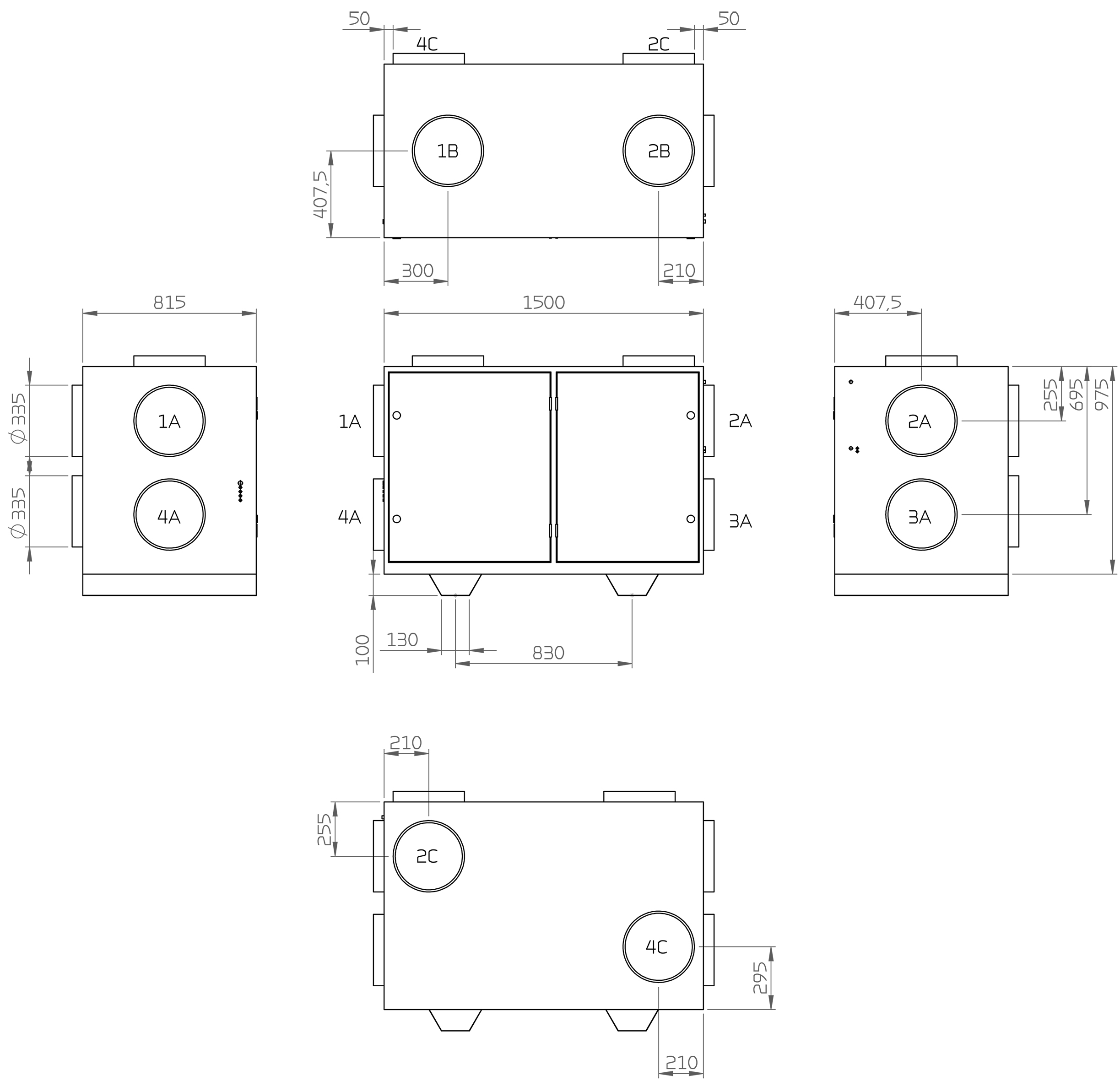

All dimensions are shown in mm. 1. Outdoor air A. Gable location Dimensional drawing VR 120 (Right version):

All dimensions are shown in mm. 1. Outdoor air A. Gable location |

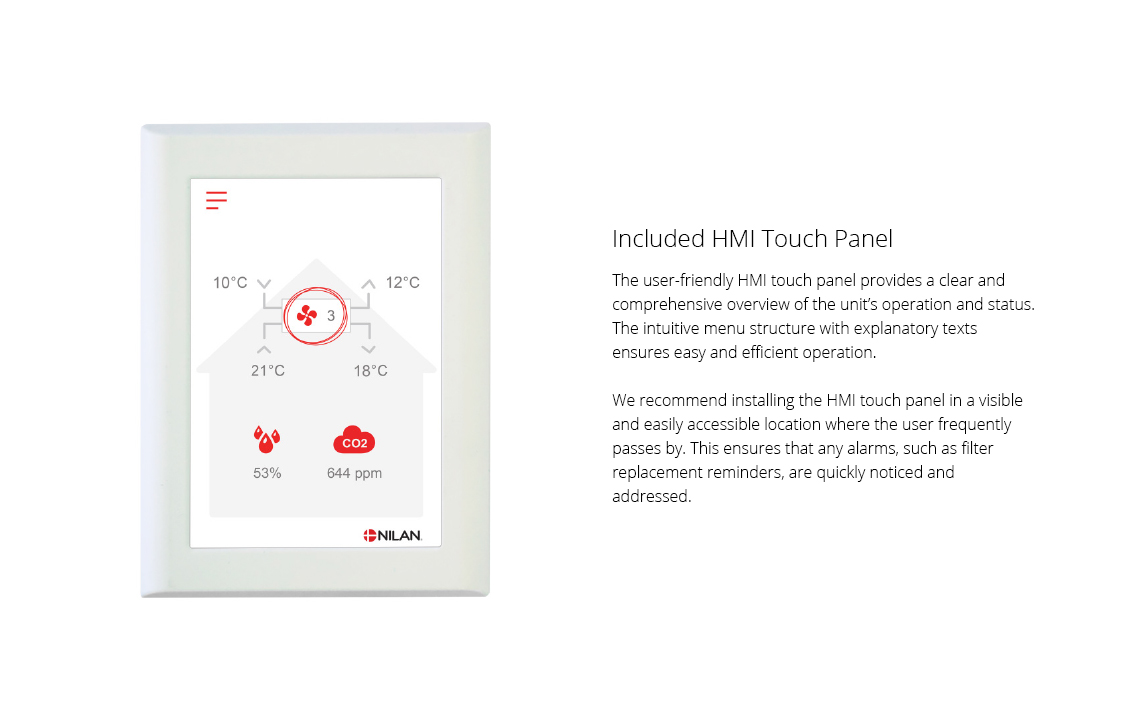

CTS602i is an advanced control system for commercial ventilation units, offering a wide range of configuration options. The control system is supplied from the factory with a basic setup that can easily be adapted to specific operational requirements and preferences. This ensures stable and efficient operation as well as optimal utilisation of the unit. The HMI touch panel provides a clear overview of the unit’s current operating status and features an intuitive menu structure that is easy to navigate for both users and installers. External communication

You can find further information about all the functions in the Software and Installation instructions for the unit.

|