HCR 800T

Efficient and quiet ventilation unit with heat and cooling recovery.

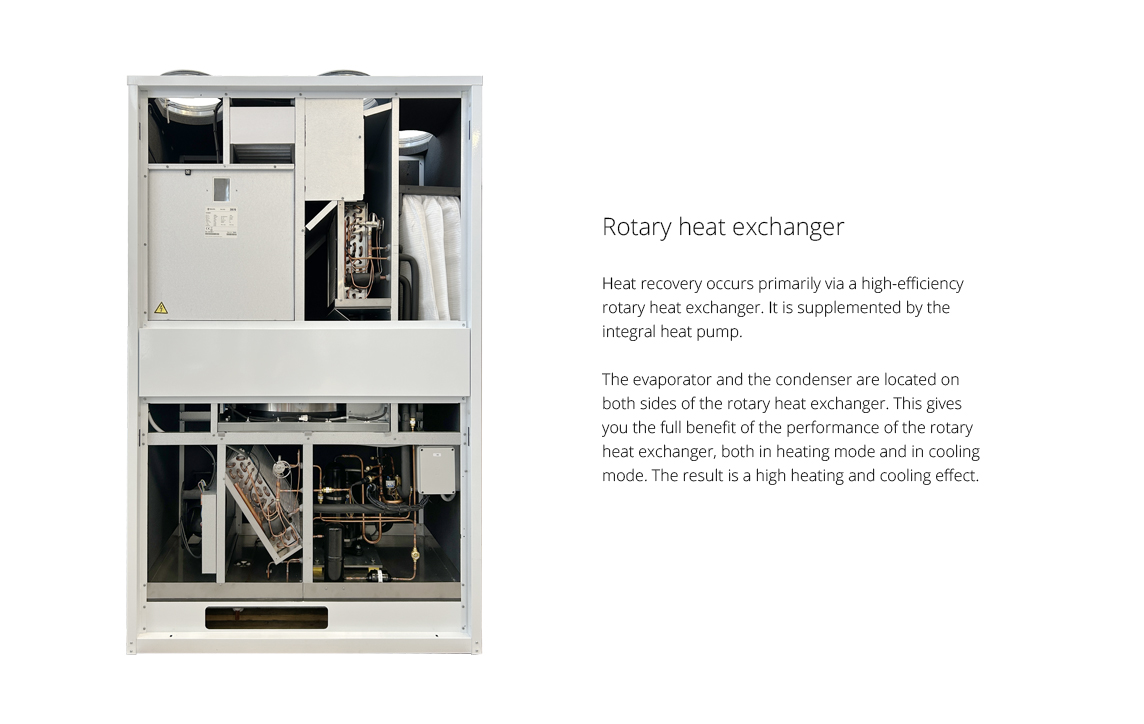

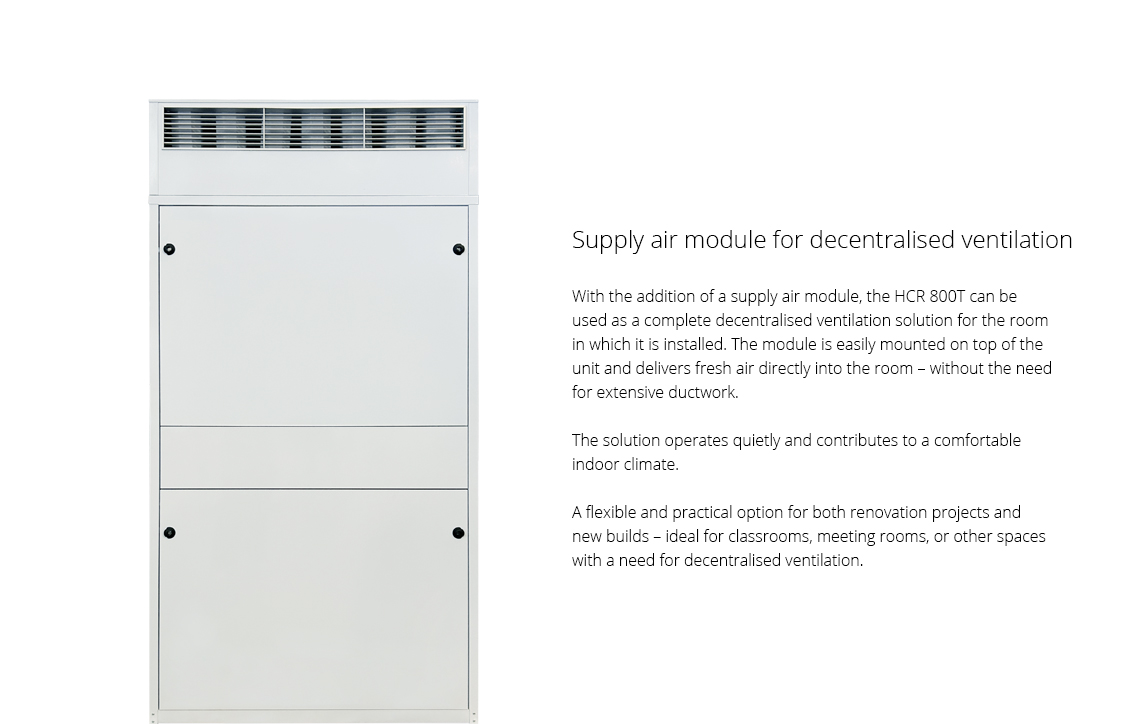

The HCR 800T is an energy-efficient and quiet ventilation solution that combines a rotary heat exchanger and an integrated heat pump to deliver optimal comfort and heat/cooling recovery. It is suitable for both decentralised and central ventilation systems and is particularly well-suited for classrooms, meeting rooms, offices, institutions, fitness areas, and other types of commercial buildings – as well as larger homes.

The heat pump features a reversible refrigeration circuit that allows the supply air temperature to be adjusted as needed – whether for heating or cooling. The advanced CTS602i control system ensures intuitive operation and efficient indoor climate regulation with low energy consumption.

The HCR 800T is designed with a focus on reliability, easy installation, and straightforward maintenance. It comes with a hermetically sealed refrigeration circuit and pre-filled refrigerant, minimising the need for additional preparations. With airflows of up to 800 m³/h, the HCR 800T meets modern requirements for comfort and ventilation – in both commercial and residential buildings.

Airflow (see planning data for SEL/SFP values)

Min : 0 m3/hMax : 800 m3/h

Heating data

Cooling data

|

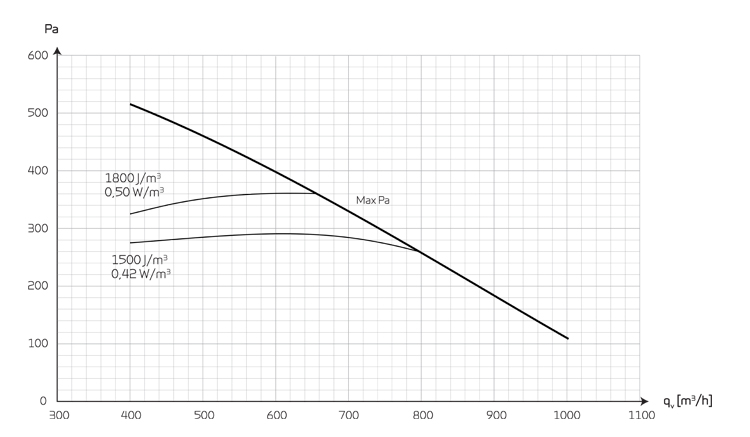

Capacity (sorption exchanger)Max Pa capacity of standard unit, Pt,ext as a function of qv, to SFP-values. Acc. to EN13053 for a unit with filters, no heating element.

|

|

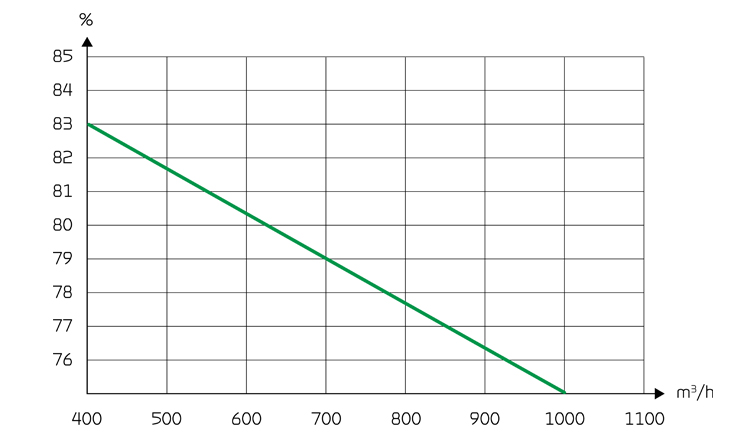

Temperature efficiencyTemperture efficiendy for rotatry heat exchanger according to EN308 (dry). |

|

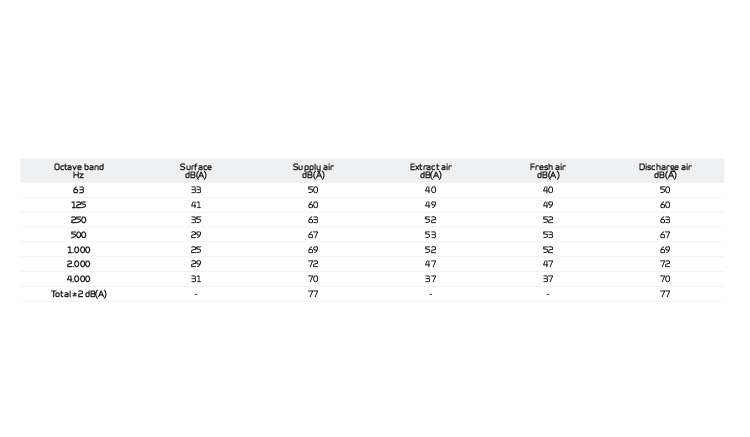

Sound dataSound data for qV = 800 m3/h and Pt, ext = 250 Pa according to EN 9614-2 for surfaces and EN 5136 for ducts.

|

|

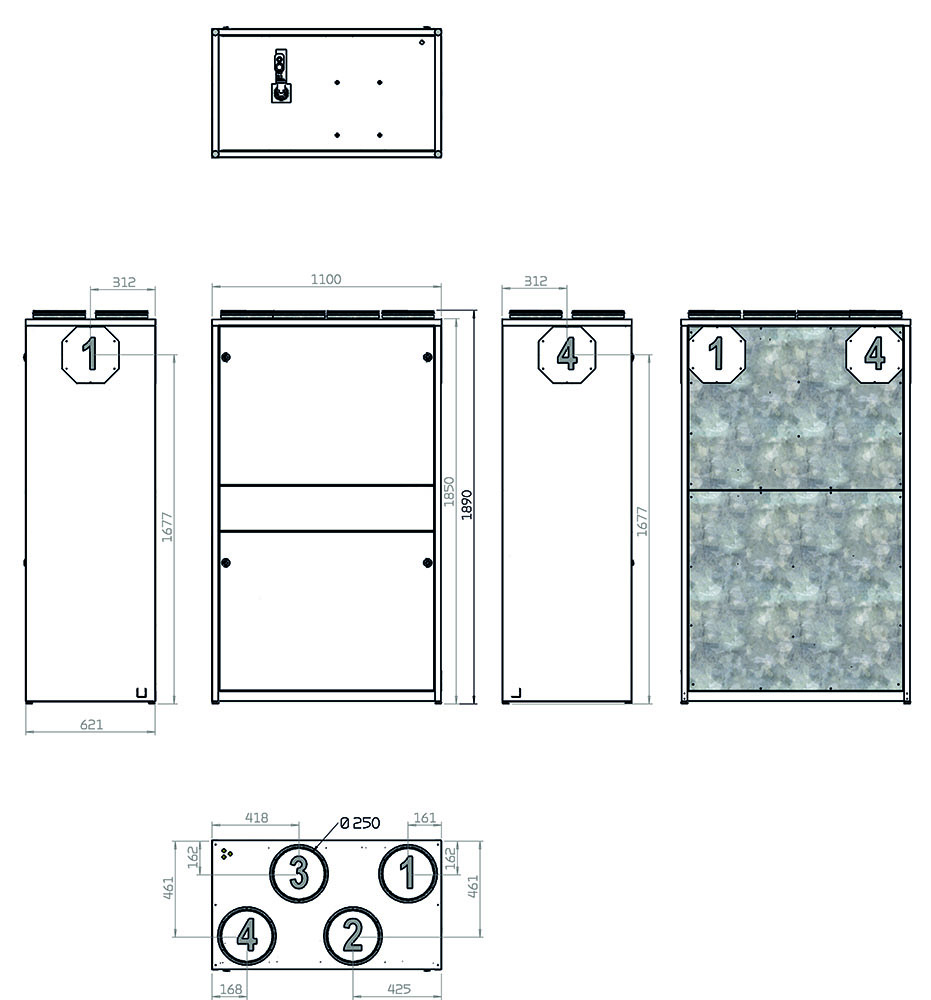

Dimensional drawing HCR (Standard):

All dimensions are shown in mm. 1. Outdoor air

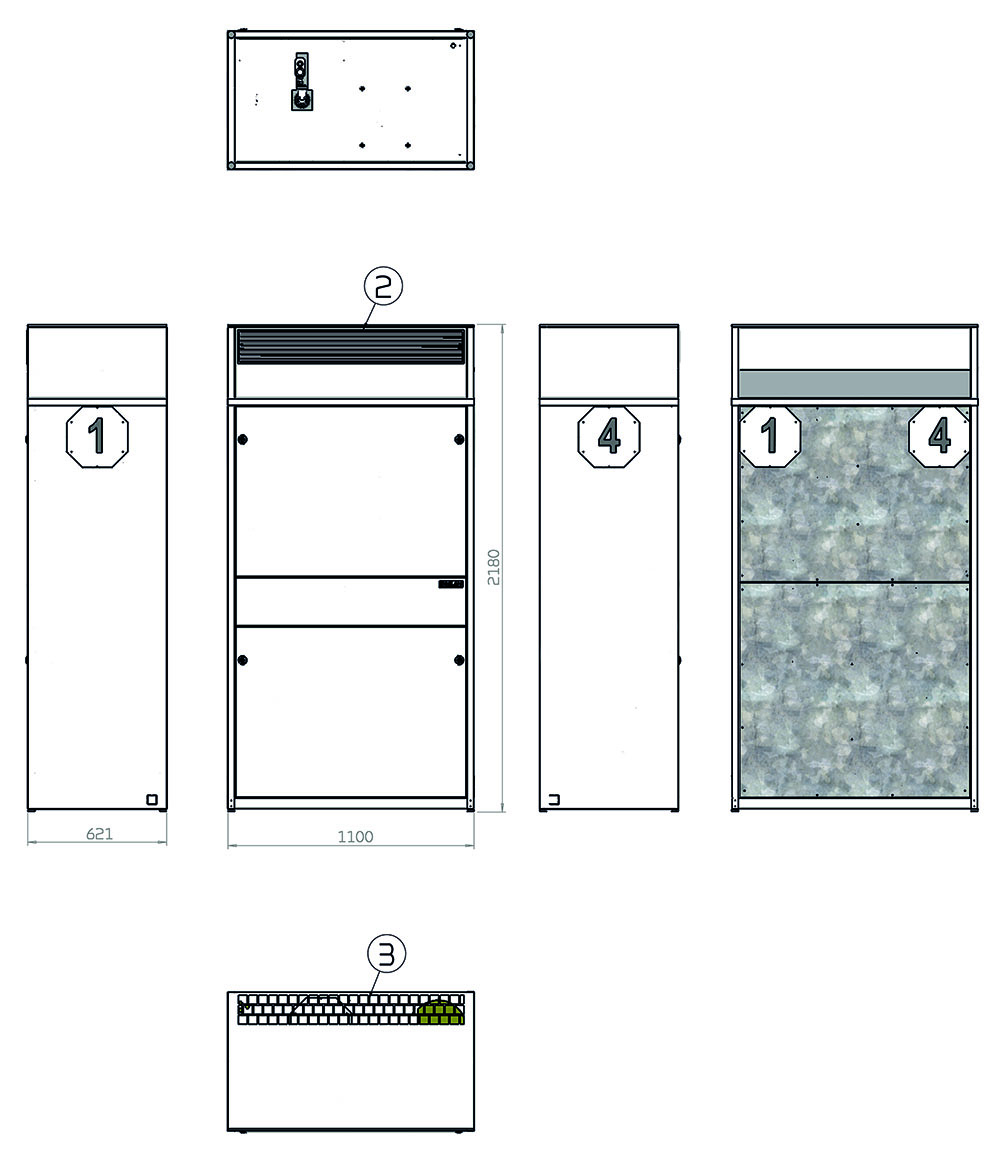

Dimensional drawing HCR (with supply air module):

All dimensions are shown in mm. 1. Outdoor air

|

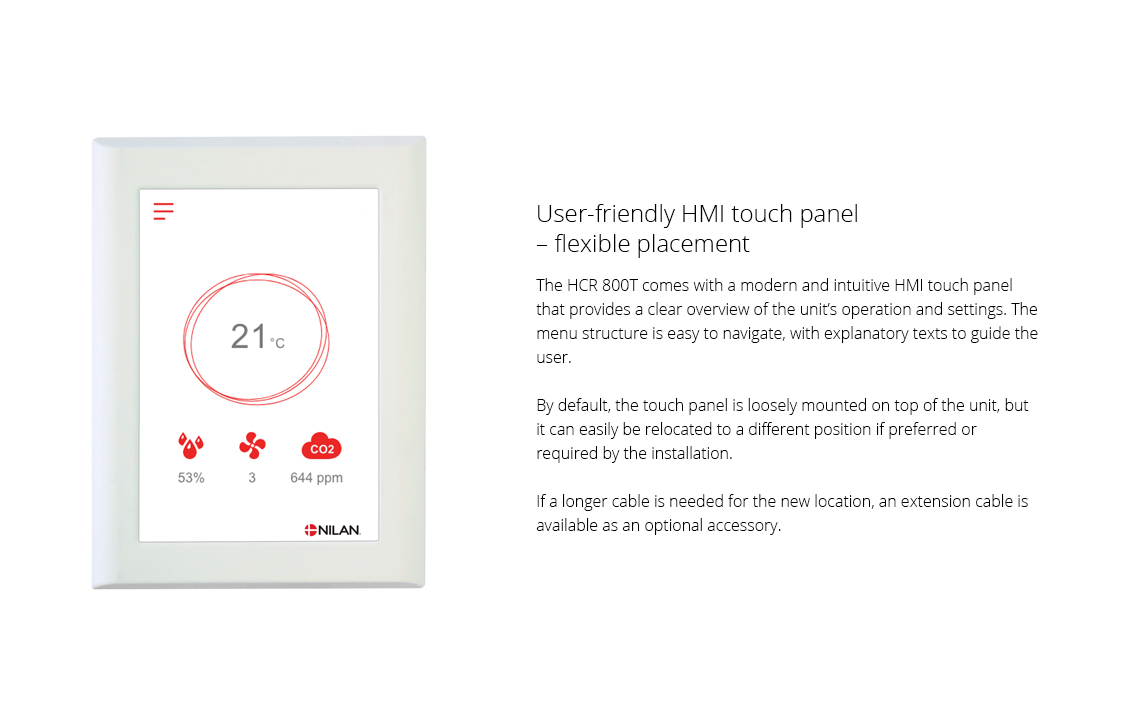

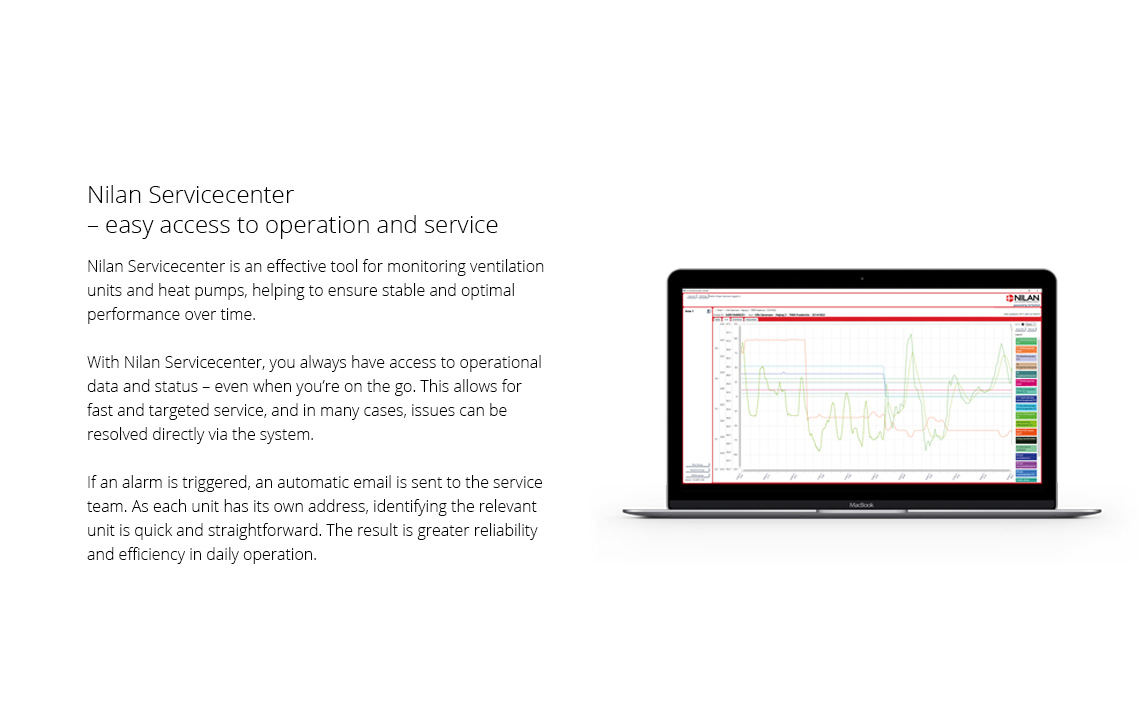

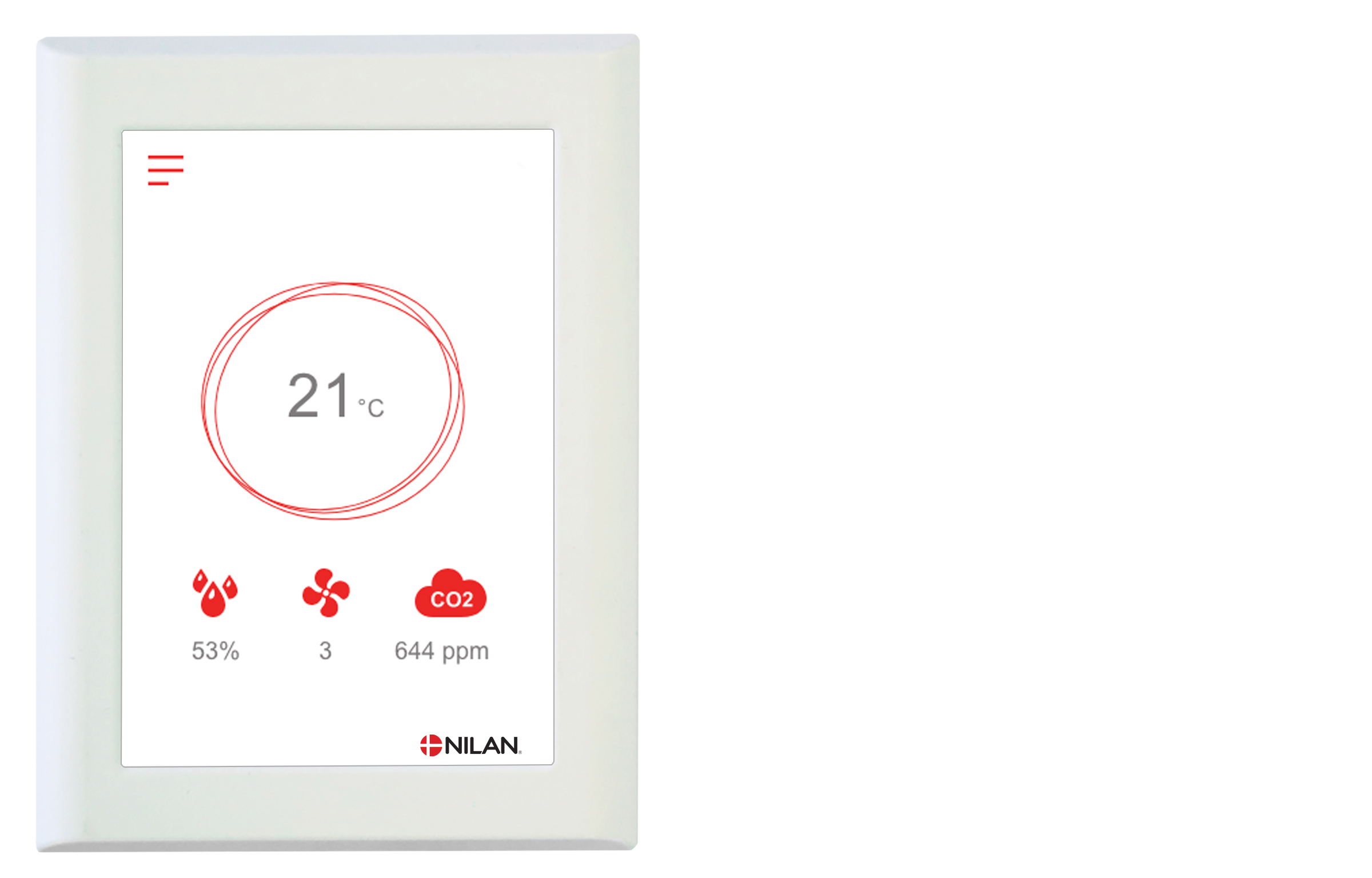

CTS602i control – advanced and flexible control for commercial units User-friendly operation with HMI touch panel Integration with external systems

You can find further information about all the functions in the Software and Installation instructions for the unit.

|