VPR 360

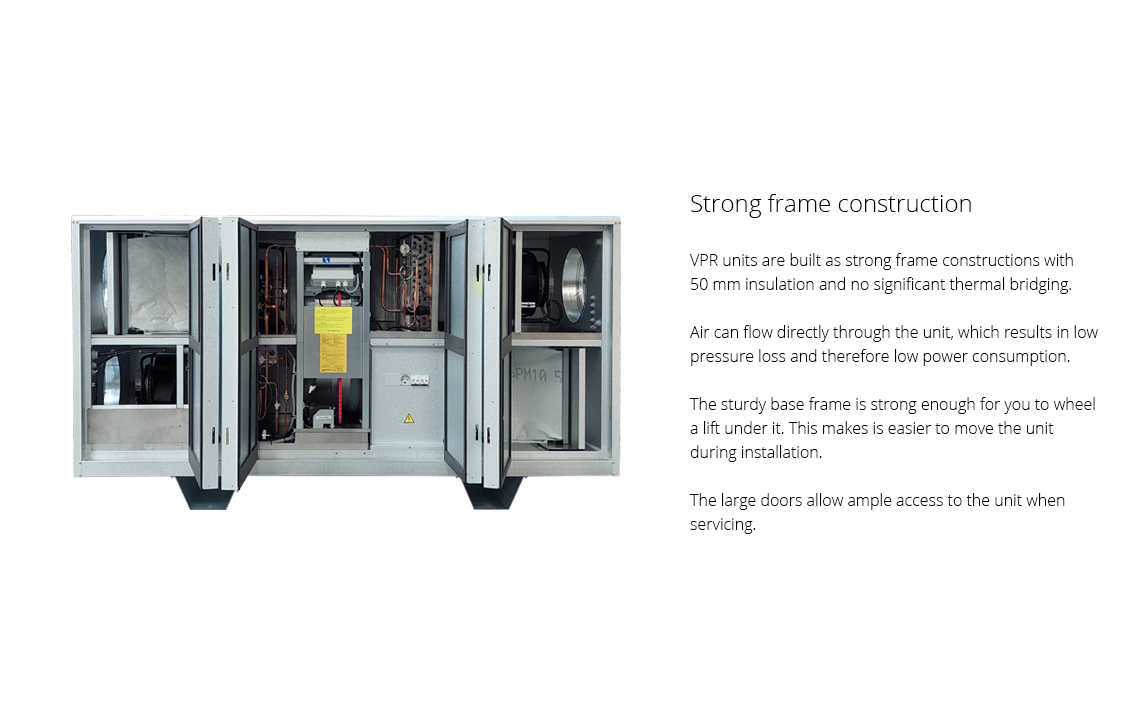

VPR 360 is a ventilation unit with heat recovery via a rotary exchanger in combination with a heat pump. The heat pump has a reversible cooling circuit and it can cool or heat supply air according to requirement.

The unit achieves a very high cooling and heating effect and therefore also a good COP. This is due to the rotary exchanger in combination with optimal positioning of condenser and evaporator. The variable speed drive compressor of the unit enables precise regulation of the supply air temperature.

VPR 360 is often used in buildings with cooling requirements, such as office buildings, retail premises, concert halls etc.

Airflow (see planning data for SEL/SFP values)

Min : 900 m3/hMax : 4150 m3/h

Motor and motorcontrol

|

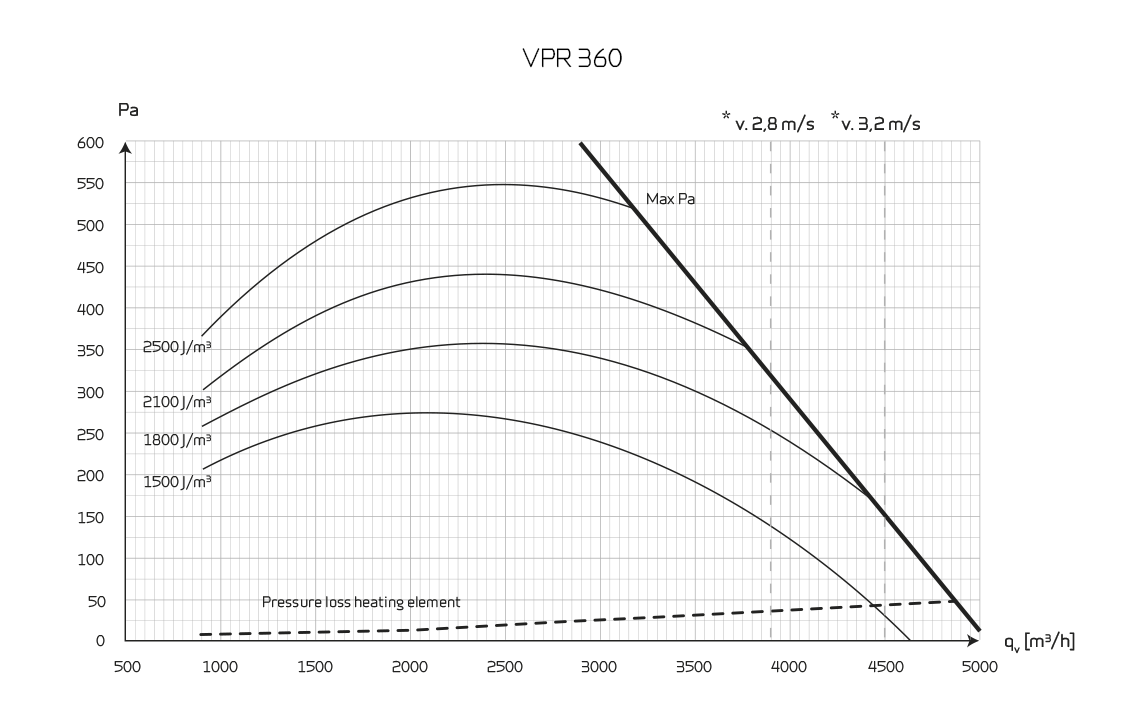

Capacity (condensation exchanger)The following design data is calculated on the basis of a condensation exchanger. Max Pa capacity of standard unit, Pt,ext as a function of qv, with regard to SFP-values. SFP-values according to EN13053 for a standard unit with ISO ePM10 >60% (M5) & ISO ePM1 50% (F7) filters an no heating element. * Airflow speed above evaporator is measured at meters per second. Attention! The SFP values are measured and stated as a total value for both fans. |

|

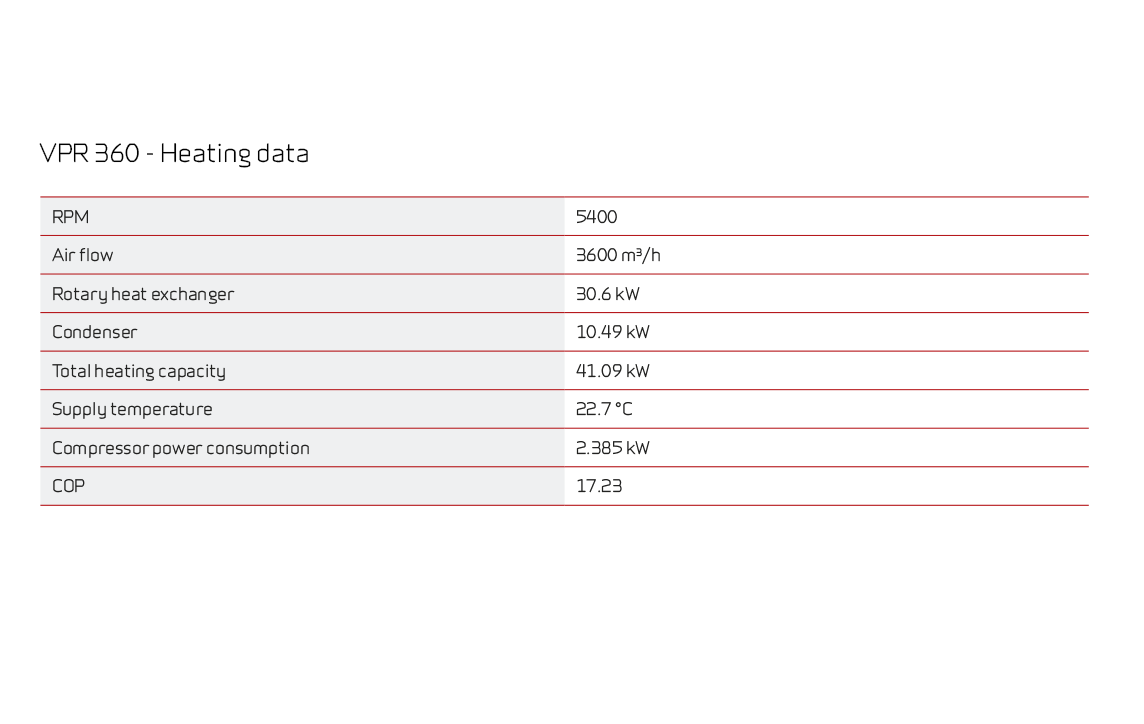

Heating data (condensation exchanger)The following design data is calculated on the basis of a condensation exchanger.

|

|

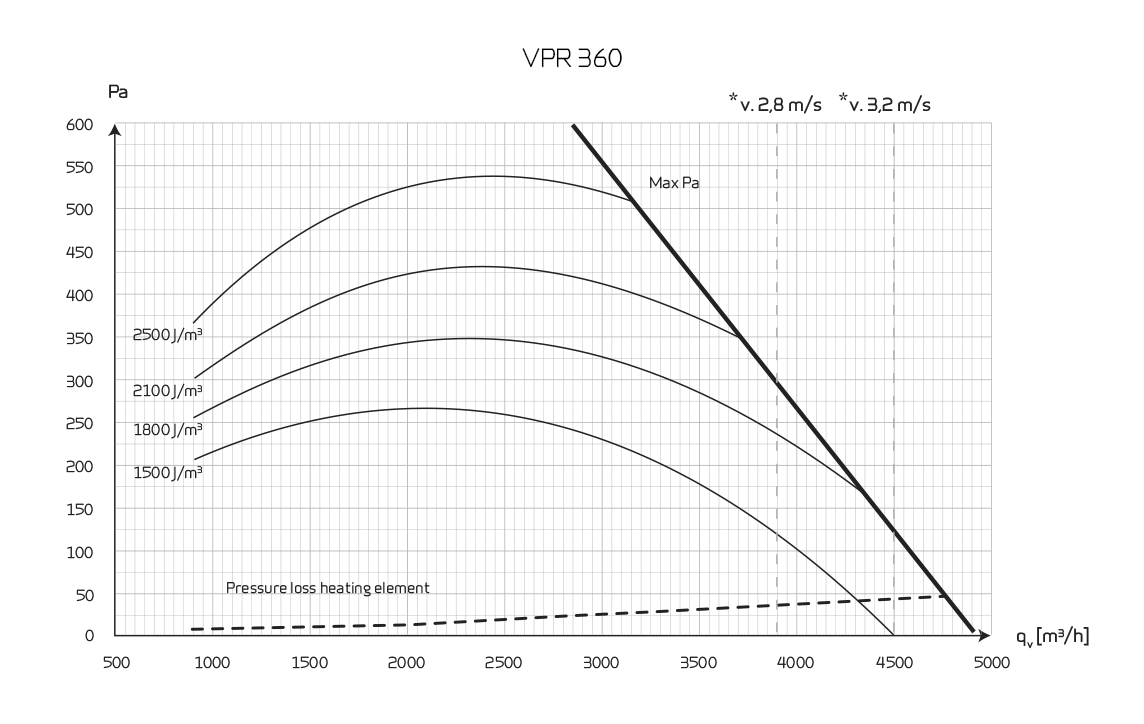

Capacity (sorption exchanger)The following design data is calculated on the basis of a sorption exchanger. Max Pa capacity of standard unit, Pt,ext as a function of qv, with regard to SFP-values. SFP-values according to EN1353 for a standard unit with ISO ePM10 >60% (M5) & ISO ePM1 50% (F7) filters and no heating element. * Airflow speed above evaporator is measured at meters per second. Attention! The SFP values are measured and stated as a total value for both fans. |

|

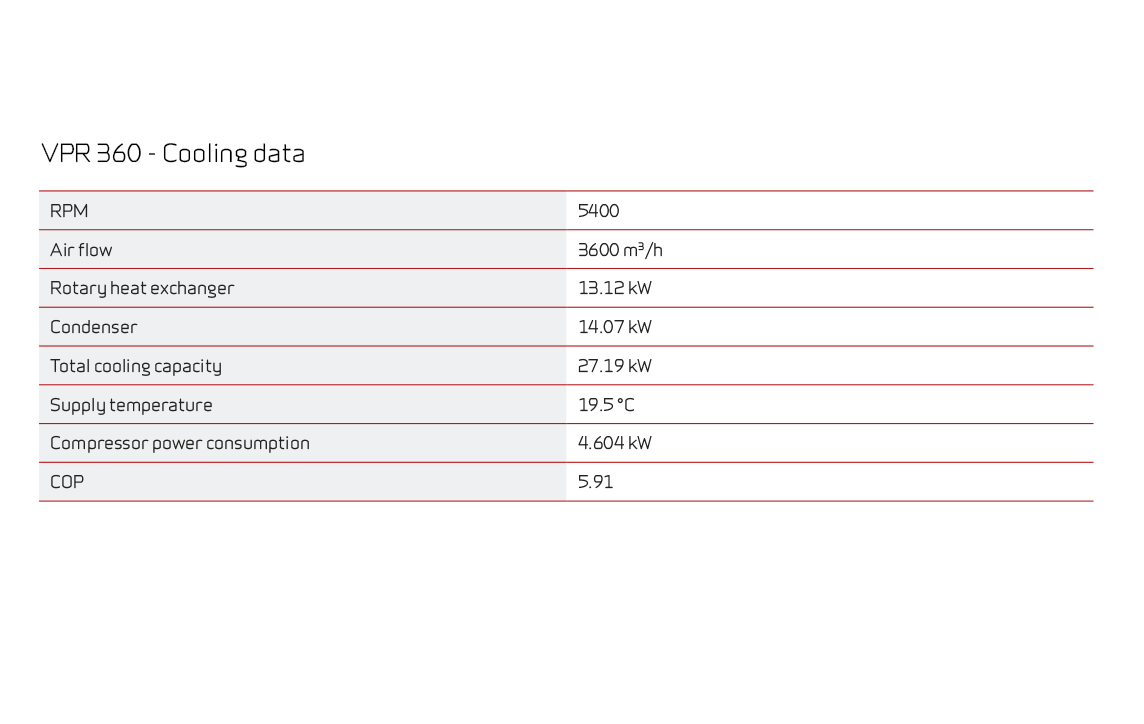

Cooling data (sorption exchanger)The following design data is calculated on the basis of a sorption exchanger.

|

|

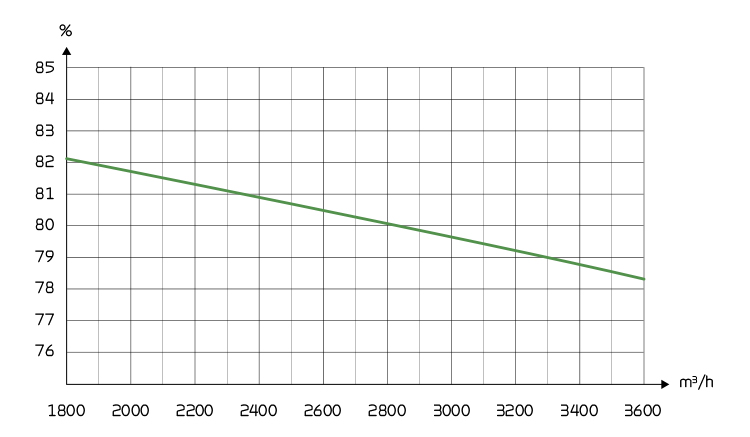

Temperature efficiencyTemperture efficiendy for rotatry heat exchanger according to EN308 (dry). |

|

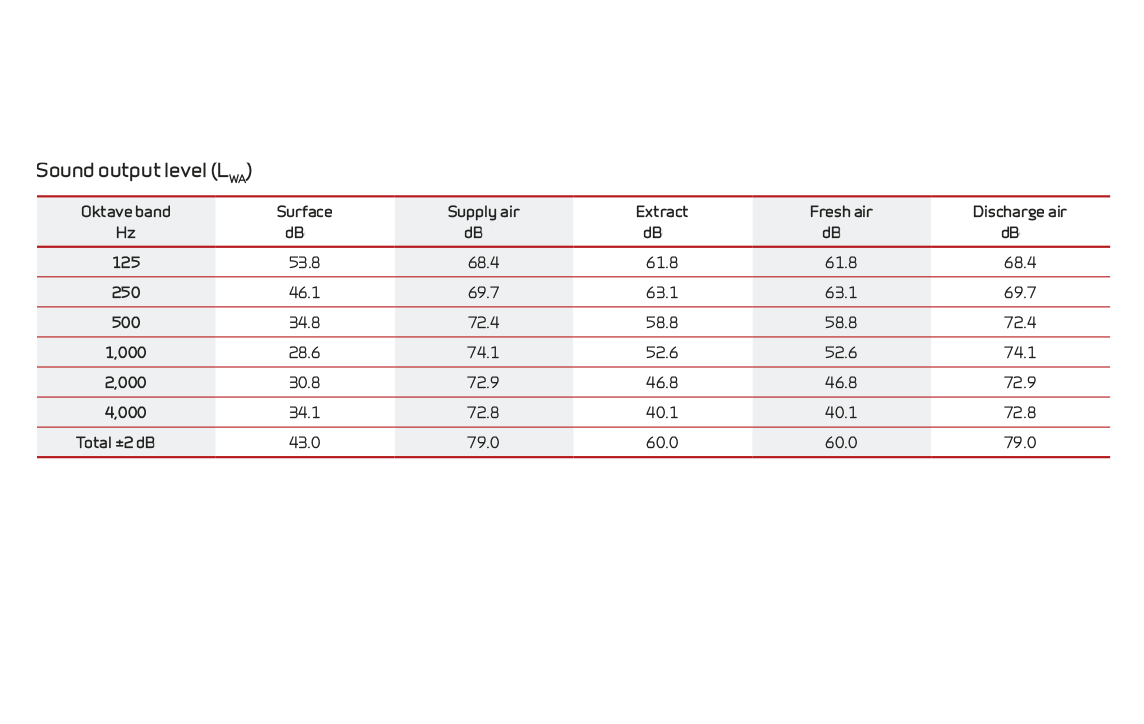

Sound dataSound data for qV = 3600 m3/h and Pt, ext = 250 Pa according to EN 9614-2 for surfaces and EN 5136 for ducts. Sound output level LWA drops with falling air volume and falling back pressure. Sound output level LpA at a given distance will depend on acoustic conditions in the place of installation. |

|

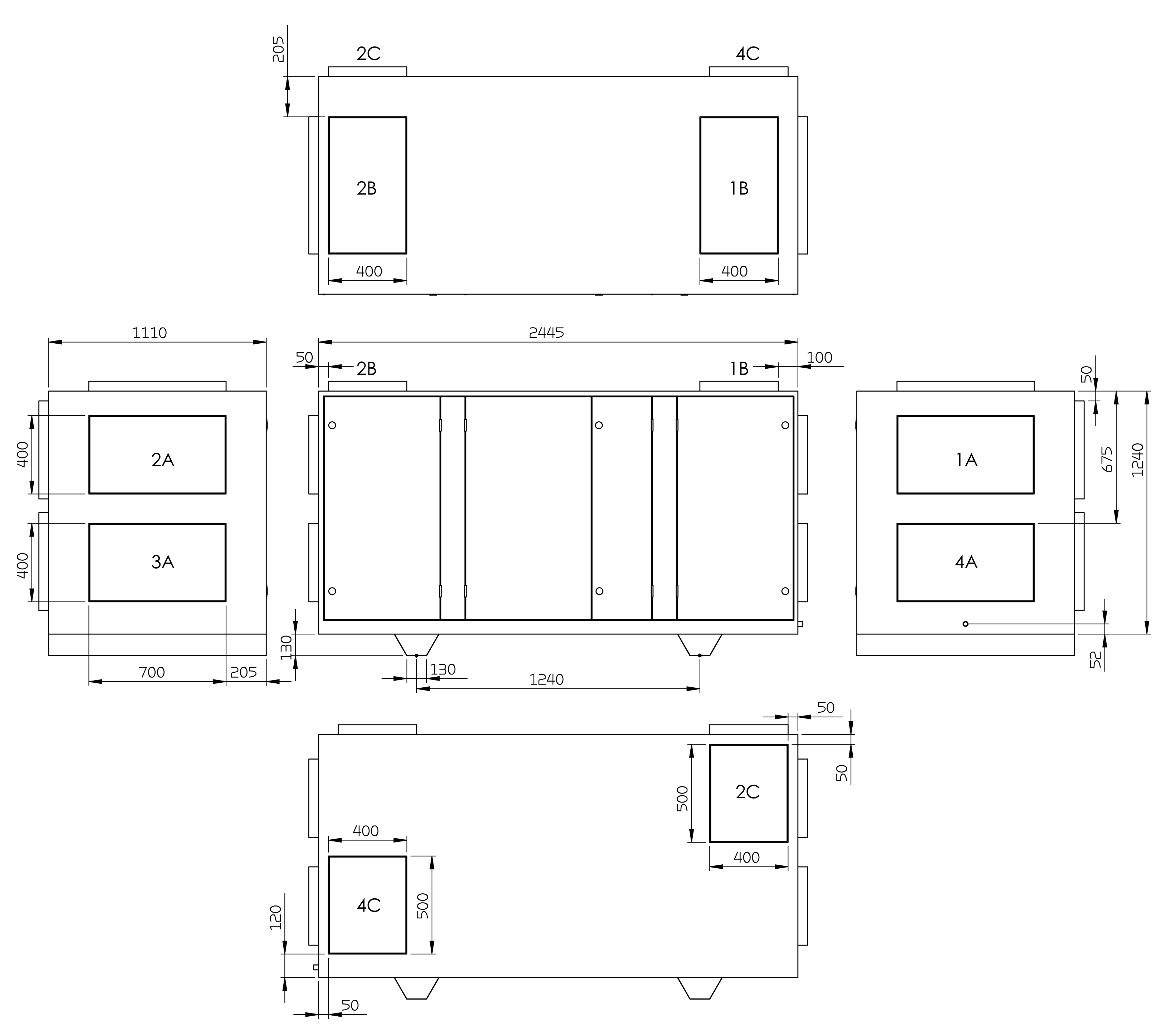

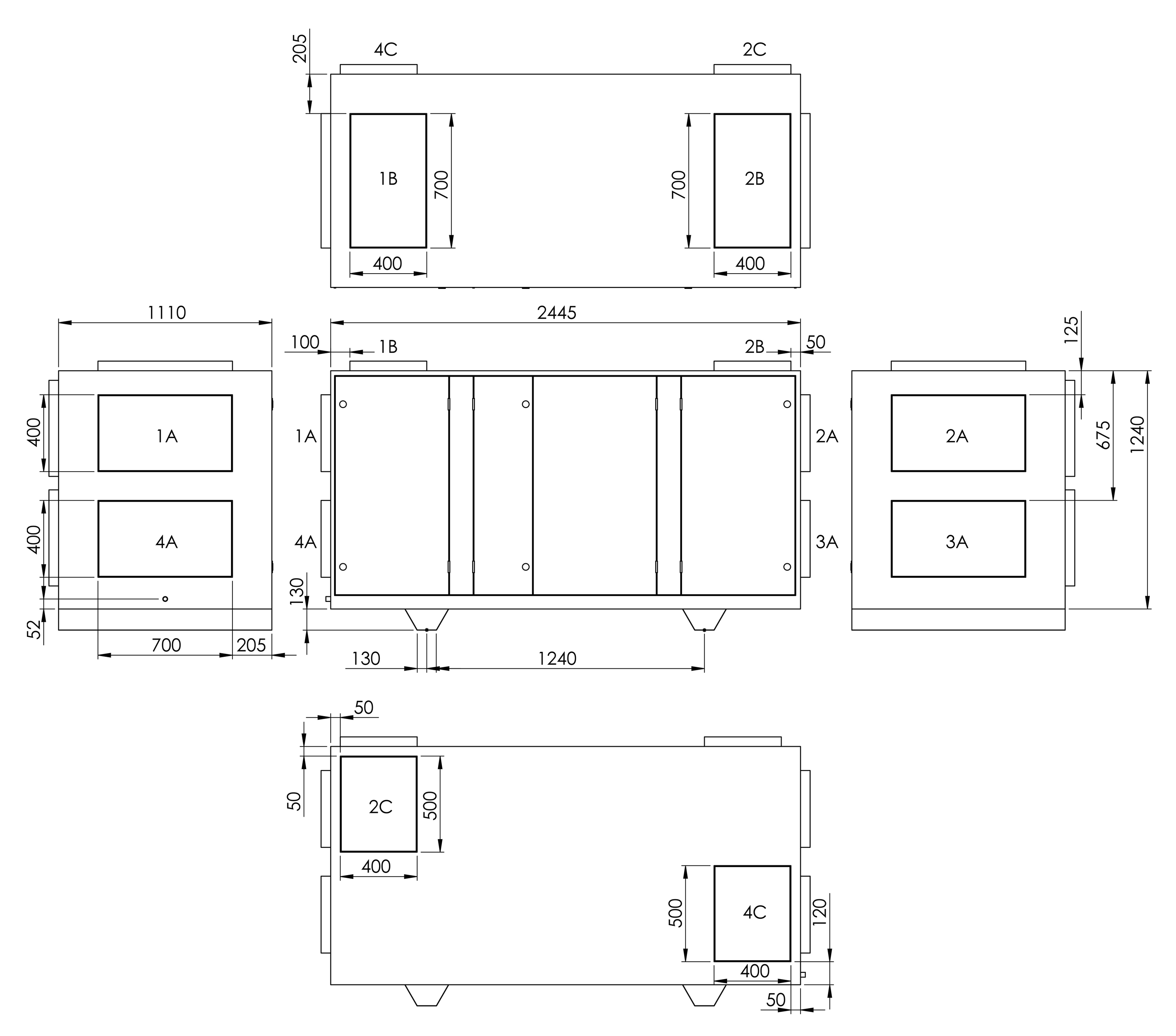

Dimensional drawing VPR 360 (Left version):

All dimensions are shown in mm. 1. Outdoor air A. Gable location

All dimensions are shown in mm. 1. Outdoor air A. Gable location |

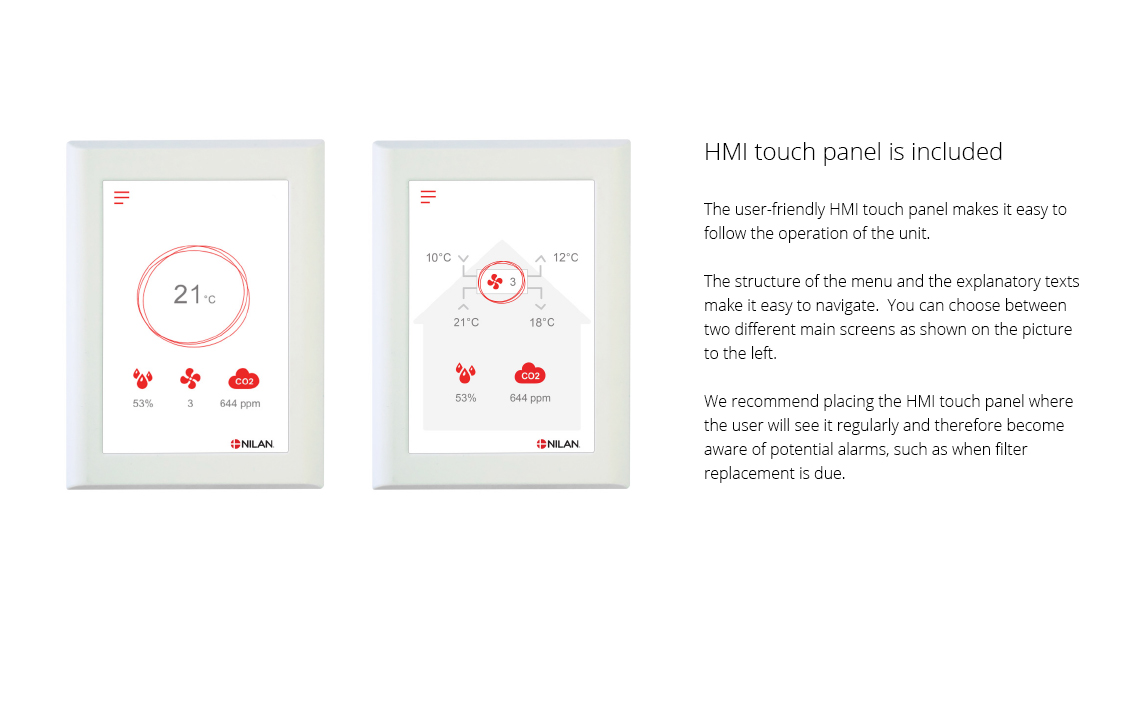

The CTS602 control system is an advanced control system with many settings options. The control system is supplied with factory default settings that can be adapted to the operational requirements in order to achieve best possible operation and utilisation of the unit. The HMI Touch panel provides an overview of the current operation of the unit, and the structure of its menu makes it easy to navigate for both user and installer. There is an option for selecting between 2 front page images for the main screen. External communication The CTS602i control unit communicates by default with Modbus RTU RS485 communication. A CTS system using this form of communication can easily be connected to the unit.

You can find further information about all the functions in the Software and Installation instructions for the unit.

|