Comfort 200 Top

Comfort 200 Top is a small ventilation unit suitable for renovation projects in apartments and terraced houses.

The unit is typically installed inside the dwelling, but because it is well insulated, you can also install it outside the climate screen. The size of Comfort 200 Top makes it highly suitable in renovation projects where space may be an issue.

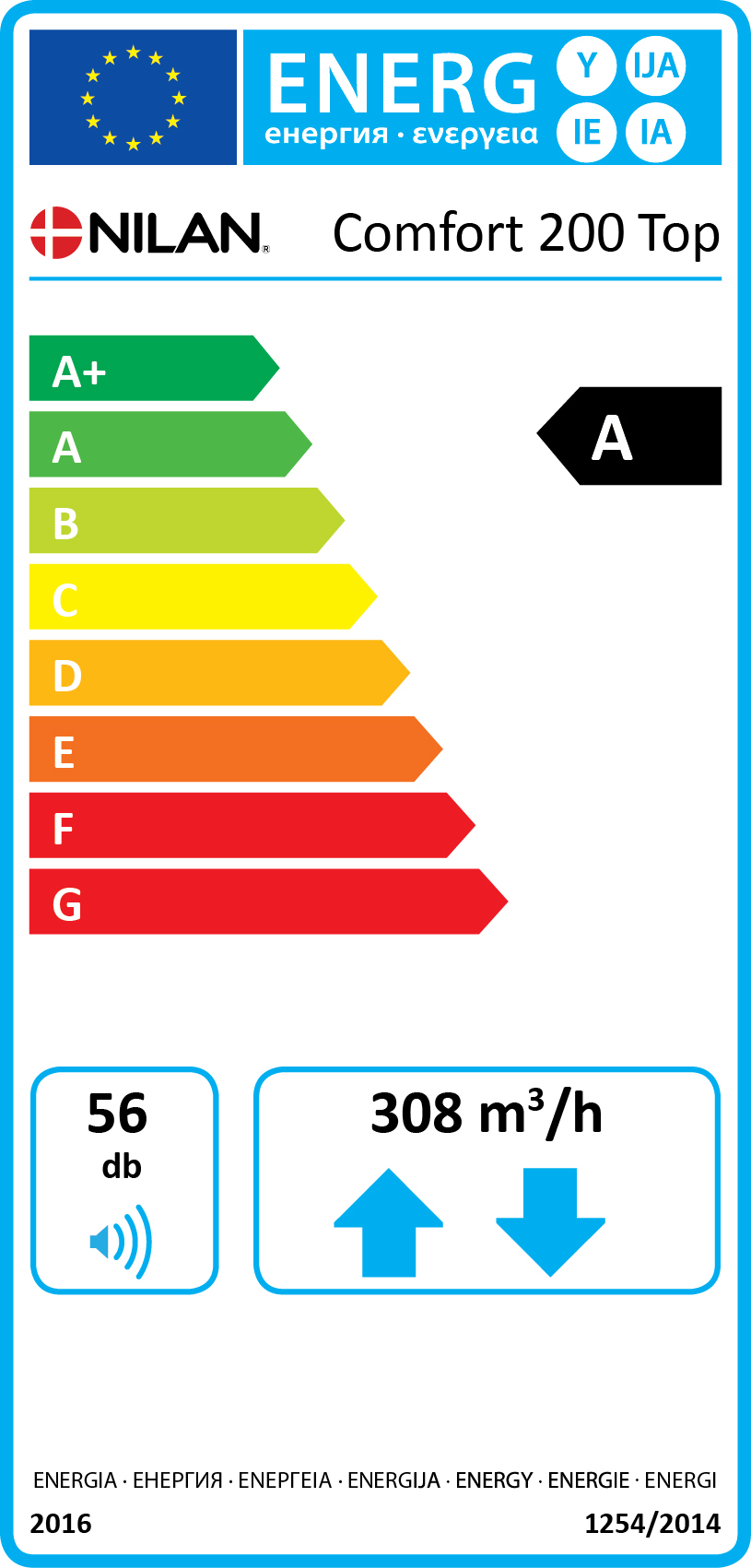

Low power consumption coupled with a high level of heat recovery means that Comfort 200 Top has been given energy label A.

Airflow (see planning data for SEL/SFP values)

Min : 75 m3/hMax : 308 m3/h

Nilan App - Control the ventilation and heat pump directly from the mobile phone

|

Nilan has developed an App with great features where the user can control the ventilation and heat pump directly from the mobile phone. The App is intuitive, easy and safe to use, and allows the user to e.g. set the room temperature. More ventilation units can be connected using the same App to control the indoor climate in e.g. both the dwelling and the holiday home. More users can be connected the same App. When purchasing a Nilan gateway, the user can access the unit via the Nilan App. Get more information on the Nilan App

|

|

|

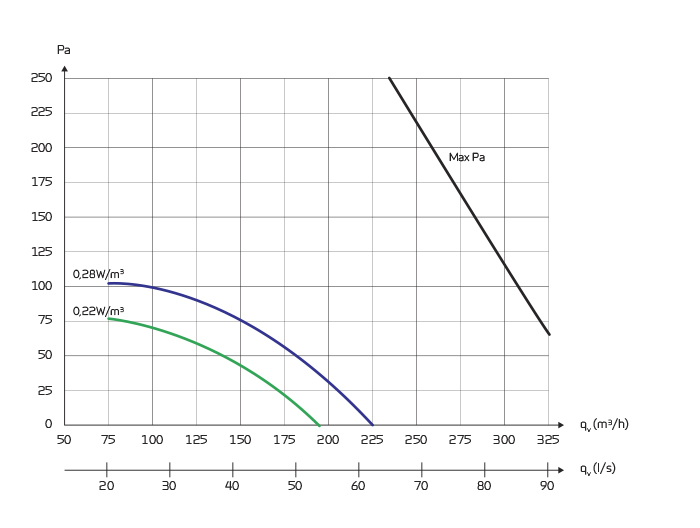

CapacityCapacity of standard unit as a function of qv and Pt ext SEL values according to EN 13141-7 are for standard units with ISO ISO 16890 Coarse 75% (G4) filters and without heating element. SEL values represent the unit´s total power comsumption for both ventilator, excl. control. Testet according to EN13141-7 Attention! The SEL values are measured and stated as a total value for both fans. |

|

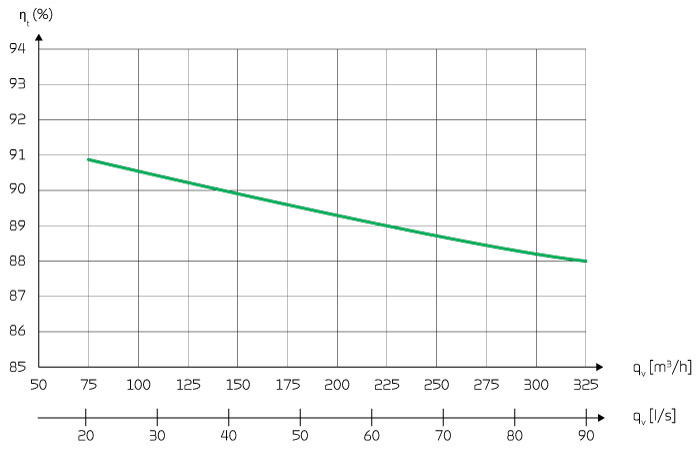

Temperature efficiencyTemperature efficiency for units with counterflow heat exchanger according to EN13141-7 (dry). |

|

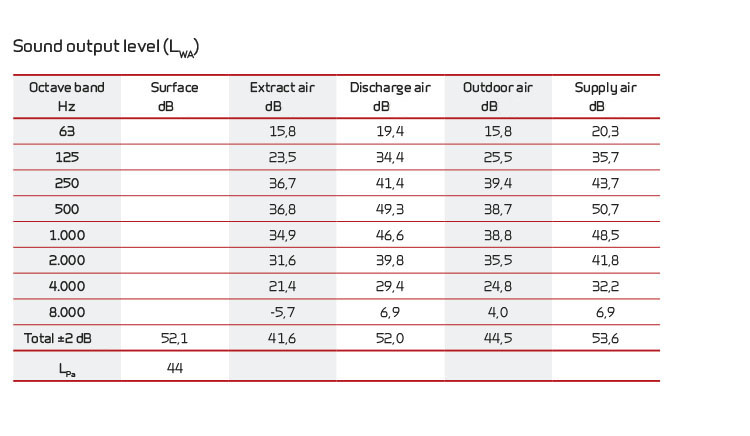

Sound dataSound data for qv = 126 m3/h and Pt ext = 100 Pa according to EN 3744 for surfaces and EN 5136 for ducts. Sound output level LWA drops with falling air volume and falling back pressure. Sound output level LpA at a given distance will depend on acoustic conditions in the place of installation.

|

|

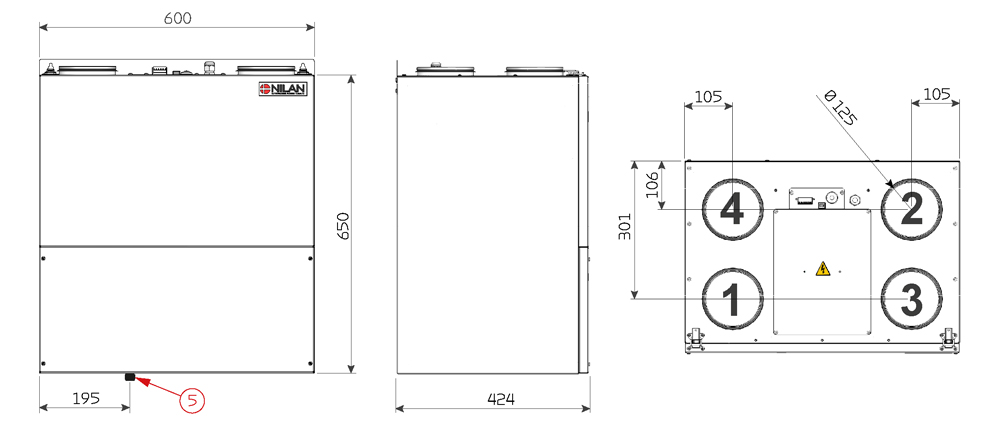

You can download AutoCad or Revit drawings with BIM data on several Nilan ventilation and heat pump solutions - the list is constantly being expanded. Click here to get more about BIM data on Nilan units Dimensional drawing Comfort 200 Top (Right version):

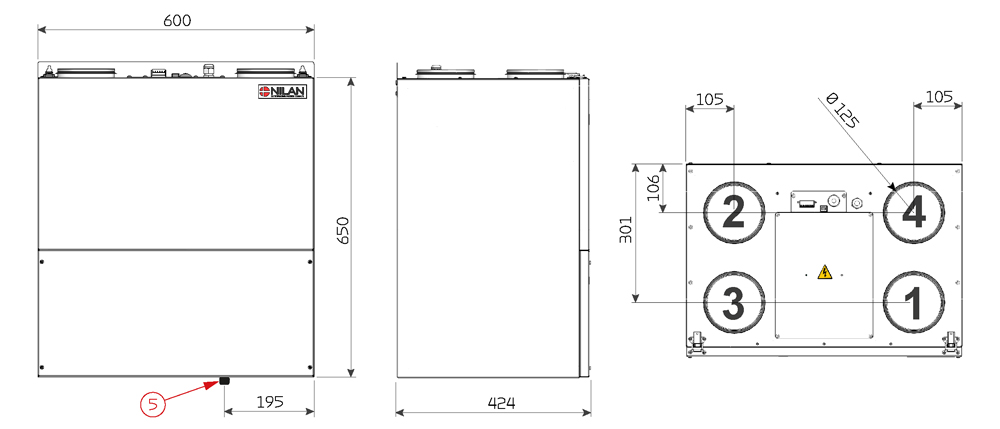

Dimensional drawing Comfort 200 Top (Left version):

All dimensions are in mm. Connections: |

CTS400 is a simple and intuitive control panel with a complex control system that contains many useful functions. On the control panel you can set the fan speed level, turn the unit on and off and see potential alarms. When installed in rental properties, hotels etc., you can lock the panel so tenants cannot turn off the unit and/or alter the fan speed level. The many functions of the control system enable you to connect, for instance, after-heating elements and a CO2 or VOC sensor. The control system includes, as standard, user selection programs, an intelligent humidity control system and an integral fire automation system. CTS400 has open Modbus communication that enables connection to external CTS systems. The Modbus connection can also be connected to a Nilan gateway cloud solution that allows you to control and monitor the unit via a smartphone APP solution.

|

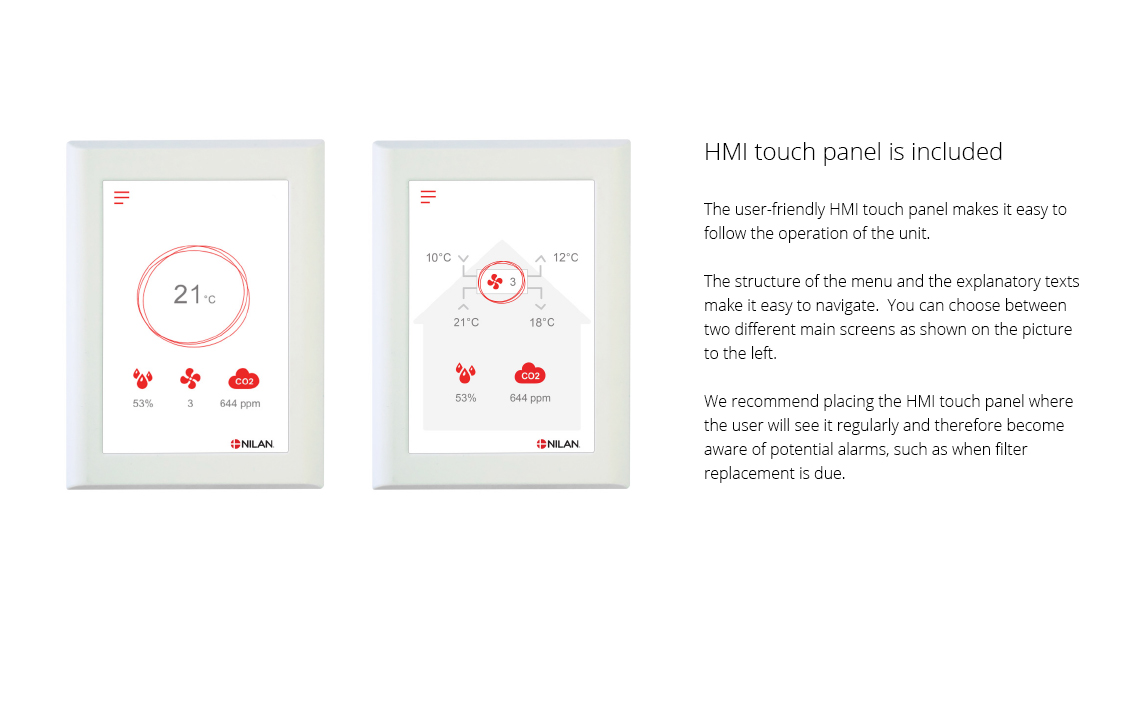

The CTS602 control system is an advanced control system with many settings options. The control system is supplied with factory default settings that can be adapted to the operational requirements in order to achieve best possible operation and utilisation of the unit. The HMI Touch panel provides an overview of the current operation of the unit, and the structure of its menu makes it easy to navigate for both user and installer. External communication

You can find further information about all the functions in the Software and Installation instructions for the unit.

|

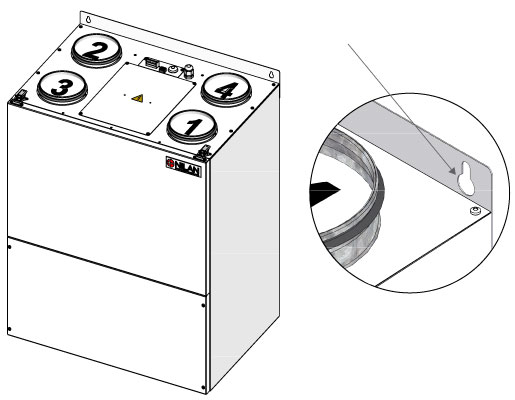

ATTENTION! When positioning the unit, you should always consider future services and maintenance. An open space of minimum 60 cm in front of the unit is recommended. It must be easy to change filters, and it must, for instance, be possible to remove the heat exchanger, and to replace fans or other components. ATTENTION! The unit must be level to enable proper drainage from the condensate tray. The unit is equipped with mounting brackets with holes for wall mounting at the top back of the unit.

|